A thread about mandrel savers gave me an idea,

Having looked at what is on the market and the stupid prices of them I decided I could make an alternative, but would what I have in my head even work never mind be any better, it will certainly be cheaper.

I had analysed the way a mandrel saver works as basically a live centre with a hole and relies upon the tailstock to apply the necessary pressure, surely this can not be hard to replicate.

Being away from home I don’t have the resources around that I am aware of but I kept my eyes open and eventually sourced for no cost exactly what I was looking for.

The battery clamping rod from an old motor vehicle is exactly the right diameter for a mandrel rod. And a bright steel 15mm rod from a disused printer.

A suitable bribe got me an hour in the machine shop before opening time.

I set about doing the hard work of turning a handle and pressing a button or two.

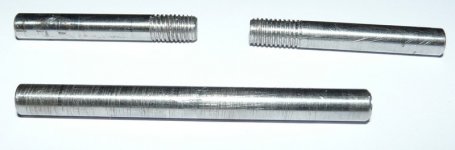

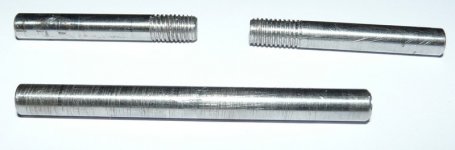

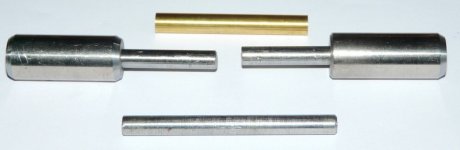

Cut the battery rod to size threaded two ends and cut and drilled the printer rod, added a corresponding thread and a suitable 60 degree cone for the centre tapers.

Mop my brow after all that hard effort and see what I have created.

This is not so much precision engineering but a prototype and time restrictions prohibit accuracy.

I am strictly off limits in this workshop.

Having looked at what is on the market and the stupid prices of them I decided I could make an alternative, but would what I have in my head even work never mind be any better, it will certainly be cheaper.

I had analysed the way a mandrel saver works as basically a live centre with a hole and relies upon the tailstock to apply the necessary pressure, surely this can not be hard to replicate.

Being away from home I don’t have the resources around that I am aware of but I kept my eyes open and eventually sourced for no cost exactly what I was looking for.

The battery clamping rod from an old motor vehicle is exactly the right diameter for a mandrel rod. And a bright steel 15mm rod from a disused printer.

A suitable bribe got me an hour in the machine shop before opening time.

I set about doing the hard work of turning a handle and pressing a button or two.

Cut the battery rod to size threaded two ends and cut and drilled the printer rod, added a corresponding thread and a suitable 60 degree cone for the centre tapers.

Mop my brow after all that hard effort and see what I have created.

This is not so much precision engineering but a prototype and time restrictions prohibit accuracy.

I am strictly off limits in this workshop.

.

.