MrJoshua

Full Member

Hi guys

A couple of years back I got a really cheap 'Power' brand bandsaw from B&Q (£50 - their own brand basically, but a clone bandsaw that goes by many brands like draper, sealey etc).

I've tolerated it until now being generally crap because it just was needed to cut stuff without any degree of accuracy but now I'm more into wood work, turning, and making pens etc I need to make it cut straight so I can get some accuracy (specially because I want to try things like celtic patterns etc!!).

I watched some youtube videos on tuning these machines up and had already adjusted it to a point where I thought I couldn't do a lot else with it. Some videos feature a machine with a missing tyre on the drive wheel, fixed with electrical tape, and producing miraculous results. Not here - it has both its tyres.

One thing that won't have helped is the thin blades and while meddling this evening the blade exploded (too much tension on it), so I've bought some half inch ones, which will in theory help it cut straight.

Basically, if I use the fence (or not) to cut a straight parallel line, the blade begins to pull to one side and try to cut a curve. I'm not sure the primary reason for this, so hoping you guys might have ideas?

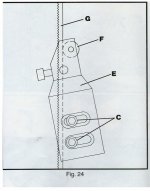

Here's the wretched thing:

Here's some more reasons why it's horrible - the blade guides aren't nice bearings (besides a thrust bearing behind) for it to roll over, and actually apply direct contact to keep it from twisting, but are little metal pegs which you can't set too close or you risk catching the blade weld and snapping it. Or just adding friction etc. So They don't much help.

Now one issue I've noticed is that while I can adjust where the blade tracks on the top wheel, it always sits on the outside edge (not exactly hanging off, but nowhere near centre) on the bottom (drive) wheel.

Not sure why this is. I would have assumed that adjusting the top would 'pull' it into position on the bottom too. But it doesn't.

This makes me think drive wheel must be sitting closer in against the machine body than the top wheel, ie they're not aligned to each other. Maybe I can shim one of them t correct this or something?

I'm not sure if this would cause the blade to twist when it cuts though - any ideas on this?

What I'd like to ideally do (besides invest in a bigger, better quality machine) is to fit proper bearings for the blade guides top and bottom, so I'll have to design and machine something suitable if I can do.

Any other obvious reasons that would cause a saw like this to cut badly though and for the blade to want to twist as it cuts?

Thanks for any useful ideas folks. :)

Jim

A couple of years back I got a really cheap 'Power' brand bandsaw from B&Q (£50 - their own brand basically, but a clone bandsaw that goes by many brands like draper, sealey etc).

I've tolerated it until now being generally crap because it just was needed to cut stuff without any degree of accuracy but now I'm more into wood work, turning, and making pens etc I need to make it cut straight so I can get some accuracy (specially because I want to try things like celtic patterns etc!!).

I watched some youtube videos on tuning these machines up and had already adjusted it to a point where I thought I couldn't do a lot else with it. Some videos feature a machine with a missing tyre on the drive wheel, fixed with electrical tape, and producing miraculous results. Not here - it has both its tyres.

One thing that won't have helped is the thin blades and while meddling this evening the blade exploded (too much tension on it), so I've bought some half inch ones, which will in theory help it cut straight.

Basically, if I use the fence (or not) to cut a straight parallel line, the blade begins to pull to one side and try to cut a curve. I'm not sure the primary reason for this, so hoping you guys might have ideas?

Here's the wretched thing:

Here's some more reasons why it's horrible - the blade guides aren't nice bearings (besides a thrust bearing behind) for it to roll over, and actually apply direct contact to keep it from twisting, but are little metal pegs which you can't set too close or you risk catching the blade weld and snapping it. Or just adding friction etc. So They don't much help.

Now one issue I've noticed is that while I can adjust where the blade tracks on the top wheel, it always sits on the outside edge (not exactly hanging off, but nowhere near centre) on the bottom (drive) wheel.

Not sure why this is. I would have assumed that adjusting the top would 'pull' it into position on the bottom too. But it doesn't.

This makes me think drive wheel must be sitting closer in against the machine body than the top wheel, ie they're not aligned to each other. Maybe I can shim one of them t correct this or something?

I'm not sure if this would cause the blade to twist when it cuts though - any ideas on this?

What I'd like to ideally do (besides invest in a bigger, better quality machine) is to fit proper bearings for the blade guides top and bottom, so I'll have to design and machine something suitable if I can do.

Any other obvious reasons that would cause a saw like this to cut badly though and for the blade to want to twist as it cuts?

Thanks for any useful ideas folks. :)

Jim

)

)