I remember posting up some bandsaw mods I did earlier in the year but I can't find them now, here's my alterations Mark.

h

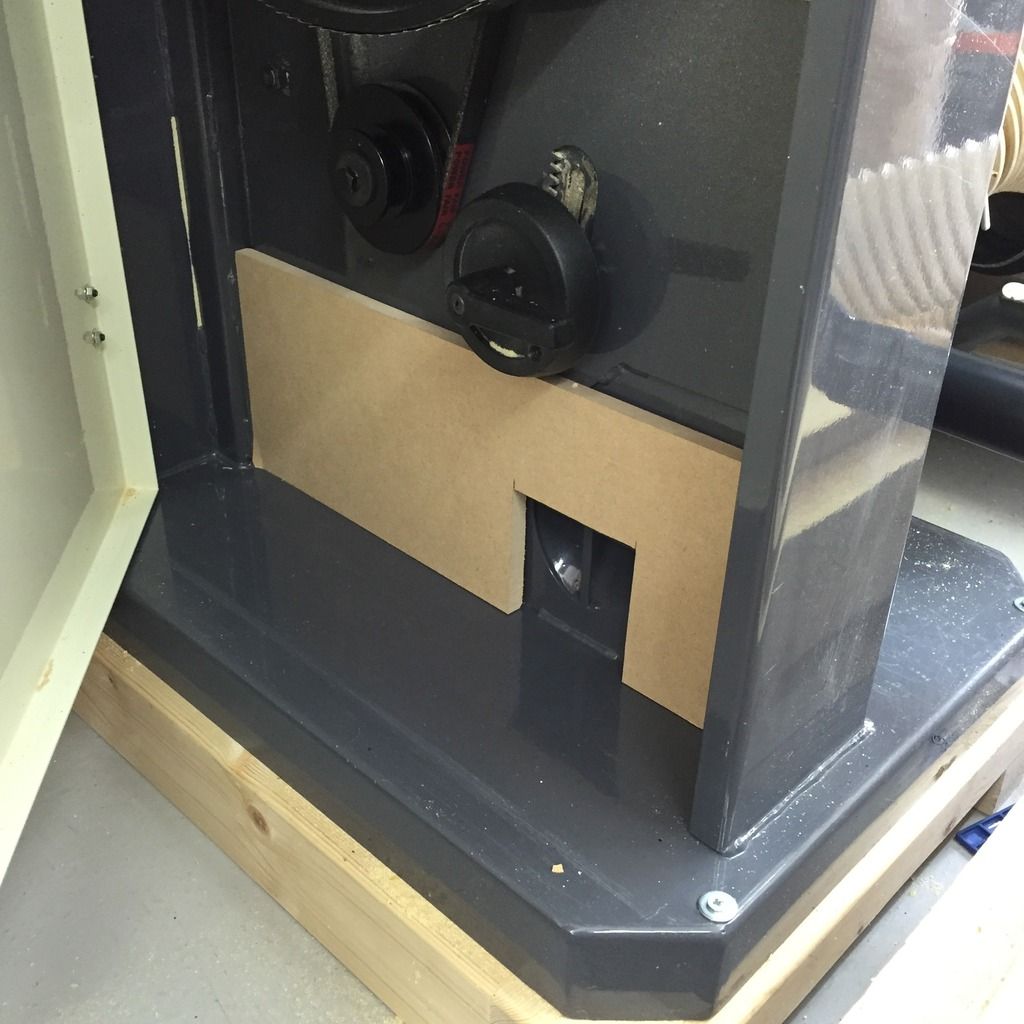

The open triangular area I thought would benefit from being sealed off so any air going into the port had to be drawn from the slots the blade passes through, to achieve this I fitted a piece of MDF to the top corner of the bottom door & covered this with self adhesive foam.

My reasoning behind doing this was as the slots the blade passess through are quite small & hopefully I could get away with reducing the 4" port down to 1 1/2".

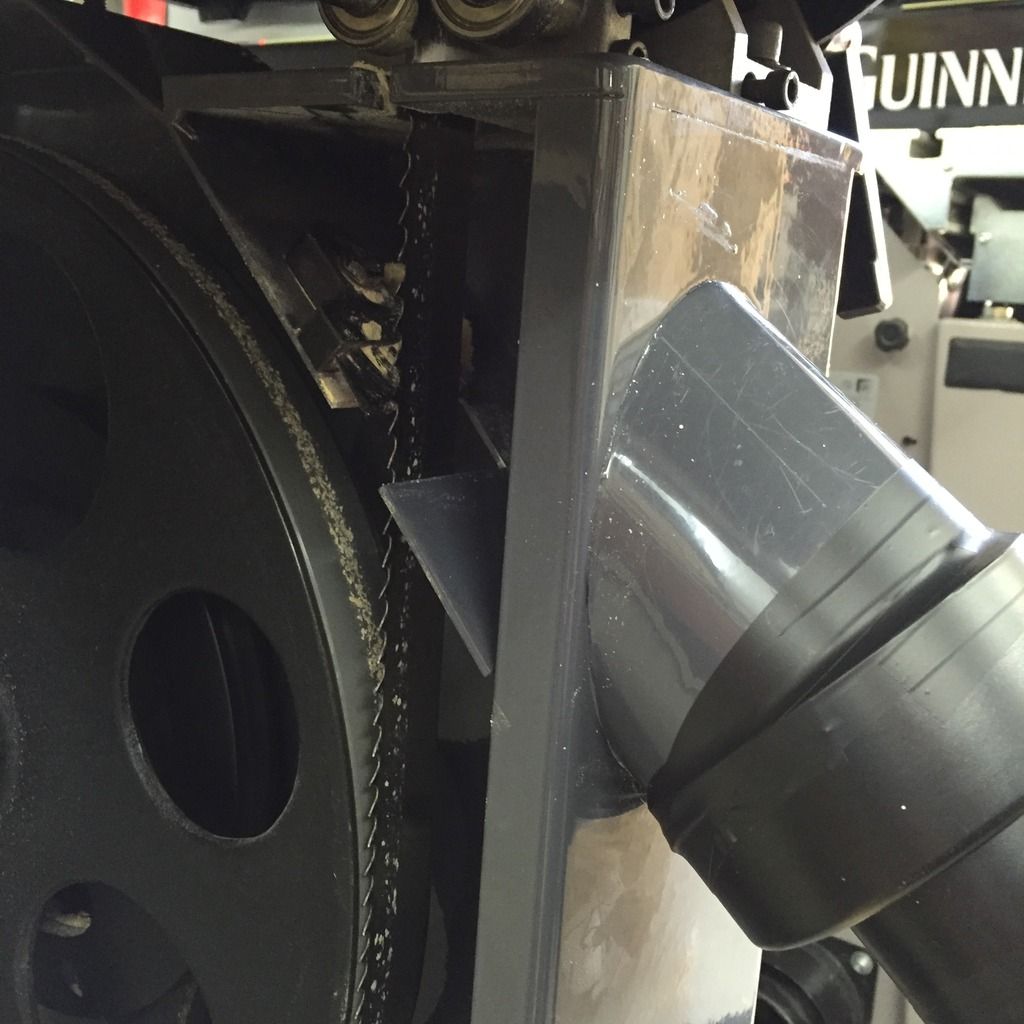

A dig around the stores came up with a some plumbing fittings which was the easiest way I could think of of making a small tee off off the main duct, this is what I came up with.

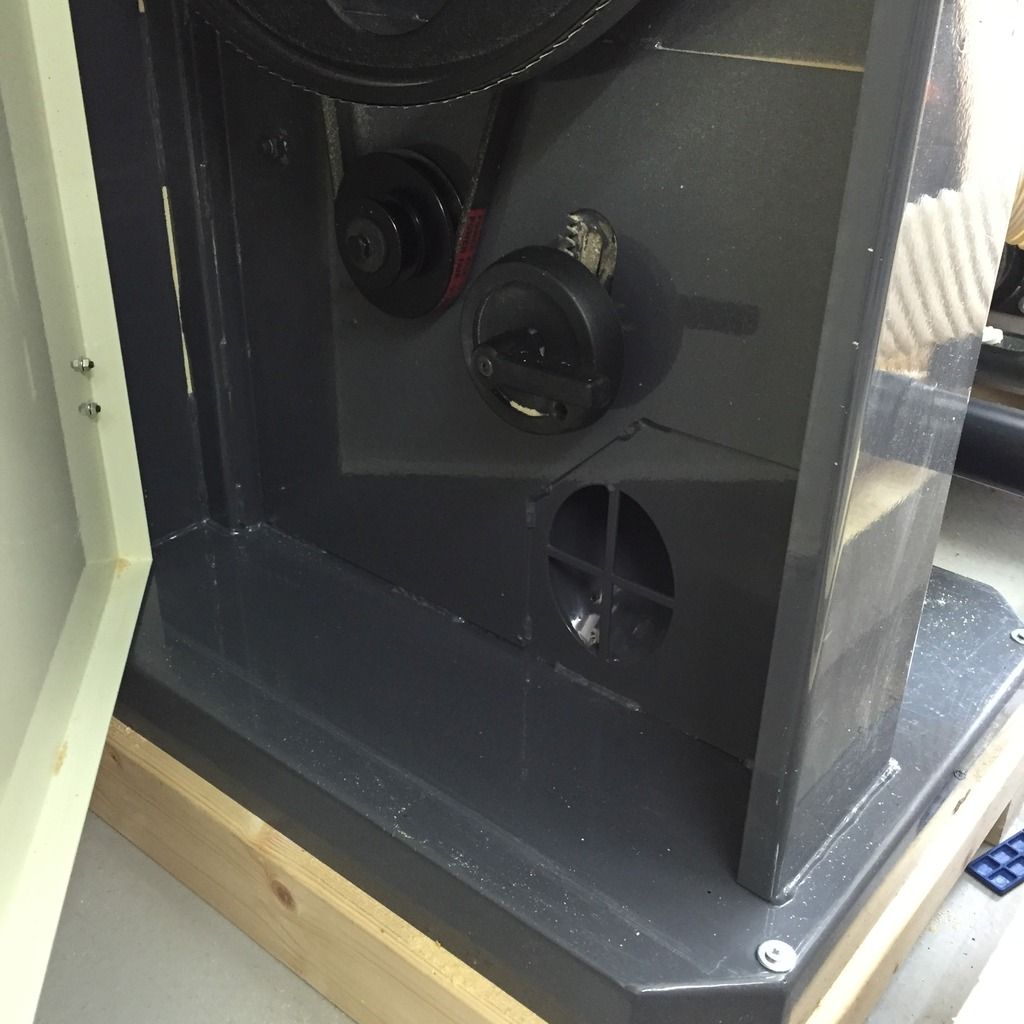

Turning the extractor on I was disappointed when placing my hand over the triangular opening to feel very little suction presumably the majority of the air was passing through the this port.

I figured reducing this port would would increase suction at the higher outlet but I was conscious of not doing this with anything that could be drawn into the extractor so cut a piece of MDF to a friction fit.