In my previous post in this thread, I mentioned using shop-made mandrels with buffing wheels purchased at a hardware store. That comment may need further explanation.

The 8" wheels that I bought came in a set of three - one 'stitched', one loose cotton, and one loose flannel. Each wheel had a 1/2" hole and the kit included a large washer for each wheel. So what I needed was a way to mount these on my lathe.

The solution was to turn set of wooden mandrels that were drilled and threaded to mount on the lathe spindle.

The mandrels are made from leftover scraps of wood - any wood works, but I have found that ash is particularly good for this purpose. I won't specify dimensions since that is specific to individual lathes, and you can easily figure out what your lathe requires. A key point is that

the holes that are drilled in the wood should be perpendicular to the grain of the wood - this is important because the mandrels will eventually be threaded to screw onto the lathe spindle, and if the starting hole is perpendicular to the direction of grain, the threads will be sharper and will last longer. Conversely, threads in end grain are notoriously weak, and in fact it may not even be possible to cut end-grain threads in some timbers.

Obviously, it is necessary to have a tap that matches the threading of the lathe spindle. I found that for my lathe, I could purchase an appropriate machinist's tap at a nearby general purpose hardware store. They didn't have the tap in stock, but were able to get it for me from their warehouse in a couple of days.

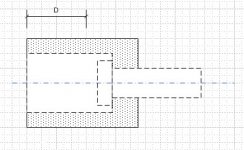

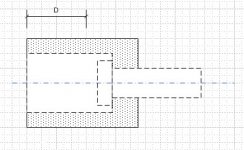

I start by drilling the larger diameter hole, and then using the tap to thread it. That hole has to be deep enough to accommodate the entire length of the lathe spindle plus and allowance for the head of the bolt that holds the buffing wheel in place. This could be done on the lathe, but I prefer to drill and tap the hole off the lathe, and then use those threads to mount the rough block the lathe for the rest of the work. Cutting the threads in that large hole takes some muscle, and I find that its just easier to do if I hold the blank in a bench vise and use a large wrench on the tap. After I thread the hole I mount it on the lathe so that the threaded hole aligns with the axis of rotation of the lathe, and the remainder of the shaping and drilling was referenced to that one axis of rotation.

Once the spindle hole has been drilled and threaded, I mount the block on the lathe to shape the body. The exact shape isn't important. Then, after shaping the outside of the mandrel, leaving the walls thick enough for strength, I mount a jacobs chuck in the tailstock and drill an on-axis hole to receive the nut that holds the buffing wheel in place. I generally put a little epoxy glue under the head of the nut so that it doesn't fall out, but that step is optional.

There are a few refinements that I add to the design:

- I usually make these mandrels in two steps. The first is the portion with the larger diameter hole. I drill that larger hole all the way through the block. Taps are commonly tapered to make it easier to start the threading process. However, if a 'blind hole' is threaded with a tapered tap, the threads at the bottom of the hole will be shallower than those further back. By drilling the hole all the way through that first block, and then running the tap all the way through, I get uniform threads over the full depth of the hole. Then, after initially shaping the mandrel, I glue a second scrap of wood on the end to provide a flat mounting surface through which I drill the hole for the wheel mounting bolt.

- Mandrels that hold buffing wheels don't have to be perfectly aligned with the axis of rotation of the lathe spindle. But when I make a mandrel for some other purpose, I will typically reverse mount the rough-turned mandrel on the lathe and turn a recess so that the mandrel seats against that fillet - that assures that the mandrel axis is always aligned exactly with the lathe spindle axis when it is used.

- I use paste wax to lubricate the threads that attach the mandrel to the lathe spindle - I assume that they will eventually wear down, but wax helps them last a lot longer. Some people also saturate the threads with thin CA glue, and then after the glue has cured, run the tap back through to clean up the threads. That's a good practice, bot it's not something that I routinely do.

- Wood expands and contracts with changes in humidity. There are two optional things that can be done if you are concerned about a mandrel getting stuck on the lathe spindle. You could just leave a couple of flat faces on opposite sides of the body so that an adjustable wrench can easily grip the mandrel - the scrap usually starts as a rectangular billet - just don't turn it all the way to round. A fancier solution is to drill an axial hole in the side of the mandrel body to receive a 'tommy bar' - when taking this approach, one might want to leave the walls of the body a bit thicker so that there is more 'meat' to grip that tommy bar.

And given that it takes about two seconds to swap a mop on a pigtail what’s the point anyway, you can only use one mop at a time.

And given that it takes about two seconds to swap a mop on a pigtail what’s the point anyway, you can only use one mop at a time.