qquake2k

Fellow

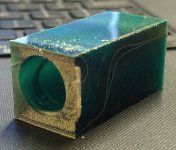

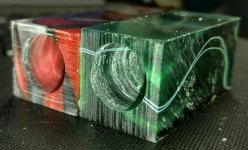

I have a hard time centering the drill bit when I drill blanks. I use a drill press vise with a prismatic jaw, and the vise is held down with tee slot nuts and studs. I've tried other methods, including a cross-slide vise, but this is what I've found works best for me. Normally, it's not an issue, as the blanks are big enough to overcome any drilling issues. But I'm thinking about trying one of PSI's Over/Under kits, which requires a 9/16" hole in the cap blank. That's a big hole! If I drill a 3/4" square acrylic blank, that only leaves 0.09375" wall thickness. I tried a practice run with a blank cutoff this morning, and you can see the results. The thinnest part of the blank is only 0.077". Now theoretically, that would leave me enough wall, because it only requires 0.045". But that's cutting it awfully close. The piece I drilled was short, and the longer the blank the more chance there is for the bit to wander. But the cap is only 1.8", which isn't very long. Now I realize, I could use a wood blank larger than 3/4", but I'd really like to have a solid black acrylic cap on it.

My question is, does anybody have any advice for drilling centered? I mark the center on the end of the blank, but that only really helps me if I'm using a brad point bit. I think my problem is, I can't tell exactly where the center of the tip of a standard drill bit is. All thoughts and suggestions are welcome.

https://www.pennstateind.com/store/PKCP6020.html

https://www.pennstateind.com/library/PKCP6000_ins.pdf

My question is, does anybody have any advice for drilling centered? I mark the center on the end of the blank, but that only really helps me if I'm using a brad point bit. I think my problem is, I can't tell exactly where the center of the tip of a standard drill bit is. All thoughts and suggestions are welcome.

https://www.pennstateind.com/store/PKCP6020.html

https://www.pennstateind.com/library/PKCP6000_ins.pdf