Hi everyone,

Today I have ran into a couple of problems that I do not know how to solve.

1) What way is the thread on a screw chuck, clockwise or anti-clockwise?

I have got the chuck off the lathe but for the life of me I just can not budge the tiny bowl that is attached to it. The bowl is only about 3 - 4 inches diameter and has about a half inch overhang from the faceplate of the chuck, so very little to grab hold of. It doesn't help that I do not know what way I should unscrew the bowl.

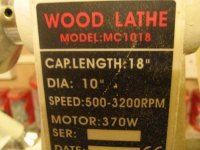

2) I have made a round "disc" out of 3/4" plywood, it will be used on the head stock for when I remove the "Nub" (Dowel) on the underside of bowls. I have made the disc a little over 9 inches, the maximum size my lathe can do is 10 inches and I am very close to that. Whilst turning it I noticed a "wobble" (left to right). The faceplate had 4 screw holes, after a while I noticed that 2 of the screws had loosened by quite a lot. I do not know if they are the cause of the wobble or are they a result of the wobble? I have never had any kind of wobble before or if there has been one I have never noticed it, the faceplate is a generic one and came with the lathe that I purchased second hand.

If the thread size on the faceplate is metric and the head stock is imperial could that be the problem and would that cause the wobble? A converter (not sure if that is the right term but it screws on the lathe and the faceplate) came with the lathe but I don't know how safe they are to use, could that be the answer? or do I really need to get a new faceplate altogether?

Or is it possible that the problem is occurring because I am at/close to the maximum diameter?

Thank you

Gary

Today I have ran into a couple of problems that I do not know how to solve.

1) What way is the thread on a screw chuck, clockwise or anti-clockwise?

I have got the chuck off the lathe but for the life of me I just can not budge the tiny bowl that is attached to it. The bowl is only about 3 - 4 inches diameter and has about a half inch overhang from the faceplate of the chuck, so very little to grab hold of. It doesn't help that I do not know what way I should unscrew the bowl.

2) I have made a round "disc" out of 3/4" plywood, it will be used on the head stock for when I remove the "Nub" (Dowel) on the underside of bowls. I have made the disc a little over 9 inches, the maximum size my lathe can do is 10 inches and I am very close to that. Whilst turning it I noticed a "wobble" (left to right). The faceplate had 4 screw holes, after a while I noticed that 2 of the screws had loosened by quite a lot. I do not know if they are the cause of the wobble or are they a result of the wobble? I have never had any kind of wobble before or if there has been one I have never noticed it, the faceplate is a generic one and came with the lathe that I purchased second hand.

If the thread size on the faceplate is metric and the head stock is imperial could that be the problem and would that cause the wobble? A converter (not sure if that is the right term but it screws on the lathe and the faceplate) came with the lathe but I don't know how safe they are to use, could that be the answer? or do I really need to get a new faceplate altogether?

Or is it possible that the problem is occurring because I am at/close to the maximum diameter?

Thank you

Gary