qquake2k

Fellow

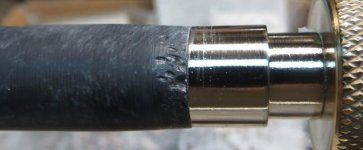

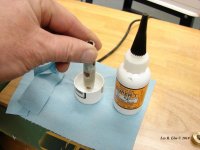

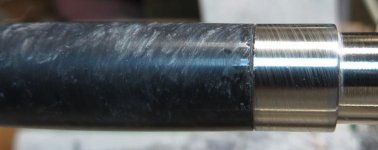

I was doing so well turning Rhino blanks... Got the lower body of this one turned and polished. Then as I was turning the upper body, this happened. I was so close, too. I hoped it would wet sand out, but it was too deep. I decided to try to fix it with thick CA. Don't know if it will work, but I'll find out tomorrow.