Tiny James

Full Member

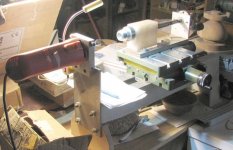

I was doing some research over the weekend for a thread cutting system as I do find threading wood and some times Acrylic a bit of a hit and miss affair when using a tap and die.

So The research lead me to Simon Hope thread cutting system. But before I buy (birthday, in June) I would like to know if anyone has this system and if it's any good also my lathe has a top speed of only 2000 RPM will that be OK with a cutter?

Here is the link

Useful Tips on The Hope Easy Set Threading Jig - YouTube

this is a better video

Turning a Wooden Thread - Simon Hope Easy Threading Jig | Stratos XL - YouTube

James

So The research lead me to Simon Hope thread cutting system. But before I buy (birthday, in June) I would like to know if anyone has this system and if it's any good also my lathe has a top speed of only 2000 RPM will that be OK with a cutter?

Here is the link

Useful Tips on The Hope Easy Set Threading Jig - YouTube

this is a better video

Turning a Wooden Thread - Simon Hope Easy Threading Jig | Stratos XL - YouTube

James

Buy a bunch of cheap aa blanks, and make one-cartridge boxes until it is an easy matter.

Buy a bunch of cheap aa blanks, and make one-cartridge boxes until it is an easy matter.