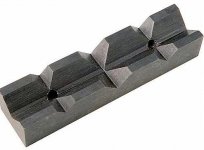

I can't remember if I bought it from Axi, but I use one similar to theirs. It clamps via a lever action rather than a thread and tommy bar, and is therefore instant to operate. I've never had an issue with it and it's served me well over the years. I clamp it to the table of my pillar drill with Klemmsia clamps, but you can use any sort of clamp if their throats are deep enough. Axi say says it opens to 33mm, but that's across the diagonal of the blank, into the v-grooves, so in fact that equates to a 23mm square blank. However, you can adjust the "factory settings" slightly, after which it will hold blanks up to about 27mm square. It will hold blanks larger than that, but you have to chamfer the corners that aren't being held, so that they pass between those two black guide bars that you can see in the Axi photo.