This is a follow-up to this thread, where I asked for some help with a Demonstrator (having come into some clear acrylic bar by a twist of fate). PeteB kindly provided a link to an article where a method for polishing the inside of a duck-call was given, using a split dowel in a drill press.

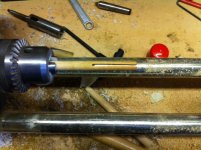

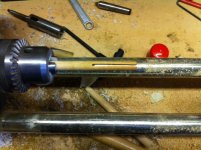

I turned down some hardwood to just under 10mm diameter, ran it through the bandsaw for about 40mm to create the split, then chucked it in a jacobs chuck on the lathe (couldn't use the scroll chuck as the jaws only close down to 12mm! ).

).

Used grits from 180 to 1200, sliding the end into the split then roiling the paper round the dowel, slid the cap over the dowel and turned on the lathe at it's slowest speed.

Then switched to T-Cut on a piece of kitchen towel mounted on the split dowel. Improvement? You betcha!

Perfect? Not yet ... First off, the threads are pretty much gone so in future I'll have to do the inside polishing first before threading. Hope that doesn't prove too troublesome. Second, the diameter is now somewhat larger than I drilled to (although this cap has had a dremel and couple of other things thrown at it, so it might no be so bad in practice). Will have to experiment further, methinks. And finally, better it may be but it's not ready for production yet.

Second, the diameter is now somewhat larger than I drilled to (although this cap has had a dremel and couple of other things thrown at it, so it might no be so bad in practice). Will have to experiment further, methinks. And finally, better it may be but it's not ready for production yet.

Thought you might enjoy this progress report.

I turned down some hardwood to just under 10mm diameter, ran it through the bandsaw for about 40mm to create the split, then chucked it in a jacobs chuck on the lathe (couldn't use the scroll chuck as the jaws only close down to 12mm!

).

).

Used grits from 180 to 1200, sliding the end into the split then roiling the paper round the dowel, slid the cap over the dowel and turned on the lathe at it's slowest speed.

Then switched to T-Cut on a piece of kitchen towel mounted on the split dowel. Improvement? You betcha!

Perfect? Not yet ... First off, the threads are pretty much gone so in future I'll have to do the inside polishing first before threading. Hope that doesn't prove too troublesome.

Second, the diameter is now somewhat larger than I drilled to (although this cap has had a dremel and couple of other things thrown at it, so it might no be so bad in practice). Will have to experiment further, methinks. And finally, better it may be but it's not ready for production yet.

Second, the diameter is now somewhat larger than I drilled to (although this cap has had a dremel and couple of other things thrown at it, so it might no be so bad in practice). Will have to experiment further, methinks. And finally, better it may be but it's not ready for production yet.Thought you might enjoy this progress report.