Hello all,

Over the weekend I’ve been stabilising a number of blanks however noticed on the 2nd batch that the lid, which is 18mm Acrylic, had I thought cracked but after taking a closer look its only surface crazing on the underside. It seems ok although not sure I want to trust it for ever.

1) Has anyone had any experience of this or similar?

2) is it safe to continue using?

3) How can I stop this getting worse or when replaced happening again?

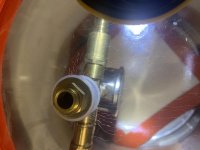

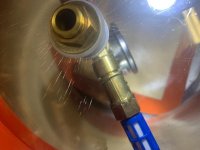

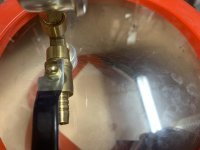

Have tried to take a few photos and will attempt to attach or include in the post, although not sure how well it’s come out or if it’s visible.

I bought as a set inc. pump off of the “great” auction site and the item was shipped from Europe. I’ve had it roughly a year but haven’t really had much opportunity to use it a much & this was probably only the 2nd or 3rd time.

I’m using Cactus Juice and I had filled the pot pretty full and used 3 ice cream containers stacked on each other with top one also being coloured blue with alumilite resin. The lid wasn’t touched by the cactus juice nor did any of the containers overflow. Have included a photo takes before the crazing happened.

Any suggestions or advice greatefully received.

Many Thanks,

Myles

Over the weekend I’ve been stabilising a number of blanks however noticed on the 2nd batch that the lid, which is 18mm Acrylic, had I thought cracked but after taking a closer look its only surface crazing on the underside. It seems ok although not sure I want to trust it for ever.

1) Has anyone had any experience of this or similar?

2) is it safe to continue using?

3) How can I stop this getting worse or when replaced happening again?

Have tried to take a few photos and will attempt to attach or include in the post, although not sure how well it’s come out or if it’s visible.

I bought as a set inc. pump off of the “great” auction site and the item was shipped from Europe. I’ve had it roughly a year but haven’t really had much opportunity to use it a much & this was probably only the 2nd or 3rd time.

I’m using Cactus Juice and I had filled the pot pretty full and used 3 ice cream containers stacked on each other with top one also being coloured blue with alumilite resin. The lid wasn’t touched by the cactus juice nor did any of the containers overflow. Have included a photo takes before the crazing happened.

Any suggestions or advice greatefully received.

Many Thanks,

Myles