Brian Rutter

Apprentice Member

Dear All,

The first memory I have of my father is 65 years ago and I was 5 years old when I helped him make his shed. He bought an old watchman's cabin from the iron works where he worked, the story goes that he paid £0-3s-6d for it, and it was very old then.

This story occurred long before the working man had cars or much money, so my Dad hired a two wheeled cart sat me on the top and set off. He loaded all the panels of the shed onto the cart, tied them down, sat me on the top and pushed the cart the 3 miles back to our home.

I do not know why but I have vivid memories of sitting on the roof of the newly erected shed and passing dad felting screws one by one which he hammered home. I can also remember being angry because he would not let me use the hammer.

During the course of its life the shed has been, a car workshop, a woodwork shop, a brewery, a photographic dark room, a distillery and an electronics workshop to name but a few. To my knowledge it has had 3 roofs and 2 sets of walls and been refelted numerous time but it is still Dad's shed.

Dad died many years ago and I have been keeping an eye on Mum who is now 97 years young, blind and in need of a lot of care.

Recently I have moved back to the old family house to look after Mum, My caring duties leave a fair bit of free time and once more I have access to Dad's shed. I have been looking for another project and have settled on making a few pens, so I am now fitting Dad's shed out for the purpose.

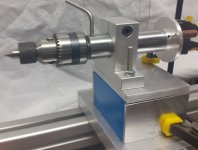

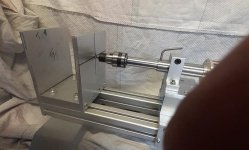

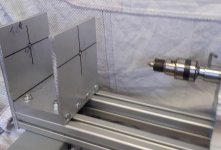

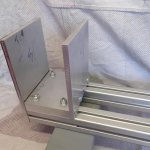

I do not have a large budget and going and buying a lathe is no fun whatsoever, I want the entertainment of building a lathe and tools.

I hope to document my build here, I am sure I will make mistakes - if you see any please shout and let me know, and if you have any advise I will appreciate hearing it, I might not take it, particularly if it involves spending money.

It will take me a few days to get organised with pictures and the like, I hope someone gets some ideas, I think I will enjoy it I hope you will.

The first memory I have of my father is 65 years ago and I was 5 years old when I helped him make his shed. He bought an old watchman's cabin from the iron works where he worked, the story goes that he paid £0-3s-6d for it, and it was very old then.

This story occurred long before the working man had cars or much money, so my Dad hired a two wheeled cart sat me on the top and set off. He loaded all the panels of the shed onto the cart, tied them down, sat me on the top and pushed the cart the 3 miles back to our home.

I do not know why but I have vivid memories of sitting on the roof of the newly erected shed and passing dad felting screws one by one which he hammered home. I can also remember being angry because he would not let me use the hammer.

During the course of its life the shed has been, a car workshop, a woodwork shop, a brewery, a photographic dark room, a distillery and an electronics workshop to name but a few. To my knowledge it has had 3 roofs and 2 sets of walls and been refelted numerous time but it is still Dad's shed.

Dad died many years ago and I have been keeping an eye on Mum who is now 97 years young, blind and in need of a lot of care.

Recently I have moved back to the old family house to look after Mum, My caring duties leave a fair bit of free time and once more I have access to Dad's shed. I have been looking for another project and have settled on making a few pens, so I am now fitting Dad's shed out for the purpose.

I do not have a large budget and going and buying a lathe is no fun whatsoever, I want the entertainment of building a lathe and tools.

I hope to document my build here, I am sure I will make mistakes - if you see any please shout and let me know, and if you have any advise I will appreciate hearing it, I might not take it, particularly if it involves spending money.

It will take me a few days to get organised with pictures and the like, I hope someone gets some ideas, I think I will enjoy it I hope you will.

)

)