Really enjoyed this and yes it was.a ureka moment i new what to after turning the last one then having a think so..

..

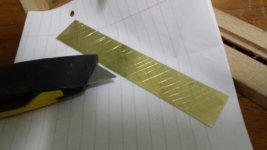

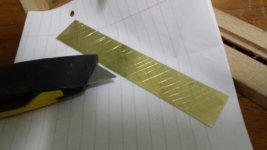

Heres the fill its muntz metal scored with a knife to give a key for the thick ca

And here are the blanks note i said blanks

As you can see running two blanks lets you swap the colours and finally the finished blank I'm not going any further until i become carbide big thanks to John for the inspiration

Thanks Frankie.

..

Heres the fill its muntz metal scored with a knife to give a key for the thick ca

And here are the blanks note i said blanks

As you can see running two blanks lets you swap the colours and finally the finished blank I'm not going any further until i become carbide big thanks to John for the inspiration

Thanks Frankie.

.

.