stiofanpadraigcrafts

Graduate Member

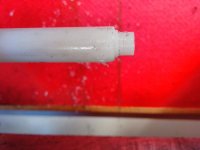

Hi guys, i just started to make my first kitless pen, i made the section ( on my second attempt after a mistake ) and all looks good. So i drilled the body on the lathe then proceeded to thread it using the matching Tap 10 x 0.75 tap and die. the problem i have is that the section seems to small for the body. it just bounces about inside. I'm using a split die so maybe i made a mistake there, i dont know. Could i have overtightened the die? or have i done something else that you can think of? any help at ll would b appreciated thanks guys