Prokraft

Apprentice Member

I thought I would share a little story of determination - I often lack some skill, I openly admit that, and sometimes wonder, when I see some other fantastic creations people make, why I bother at all but on this occasion things were a bit different.

I had previously made a sharpening jig from wood - not good particularly in a damp workshop that seems to go from minus 6° to hotter than the sun in 20 minutes, so off I went to buy one.

I love tools, I love good value too and I couldn't seem to find a reasonable one until I came across one on Ebay. Sadly I sell on Ebay and it is a necessary evil to make a living at the moment they are a market leading platform with no interest in customer service to either customer or seller they just collect fees, but I did find a chap who makes these things.

In order to not give Ebay any more money I sent him an email - he never responded and that was like a red rag to a bull.

I had somewhere in one of the old sheds an arc welder, I think I had it to mend some gates as it was cheaper than getting a man in.

I dug it out, a 16 amp thingy with some wires - will it work in a 13 amp socket? - probably if I turn it down a bit, there's a big dial on the front with some numbers that mean something to somebody (but not me) turn it left a bit.

I got a bit of steel at a grand cost of about £6 - they make this conveniently that one size square section slides into another - very clever (and damn useful too), I got some grey sticks, Darth Vaders helmet and a hacksaw (no angle grinder - I need the excercise).

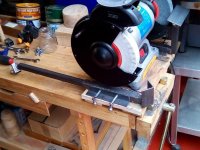

With sheer determination I made a sharpening jig as you can see - it is not pretty, it looks rather like the welding witch has been and spat on it but by 'ek it's solid. I used a pillar drill and I also have a tap and die set for doing the locking nuts (1 bolt cut in half, hole in each half an old nail through and you have a jointed locking thingy). Getting the length correct on the spindle jig was tricky - especially getting the hole centred on the 90° angle - it took 2 goes.

It works very well and if you don't have to buy a welder or tools dirt cheap - but most importantly - it was bloody good fun.

So if you get a chance to ever make your own tools have a go - as you can see I am no engineer and even I managed it -not only will you save a few quid you get a warm feeling of satisfaction every time you use it.

I can't recommend a 16 amp appliance in a 13 amp socket for obvious reasons but I am still here to tell the tale

I had previously made a sharpening jig from wood - not good particularly in a damp workshop that seems to go from minus 6° to hotter than the sun in 20 minutes, so off I went to buy one.

I love tools, I love good value too and I couldn't seem to find a reasonable one until I came across one on Ebay. Sadly I sell on Ebay and it is a necessary evil to make a living at the moment they are a market leading platform with no interest in customer service to either customer or seller they just collect fees, but I did find a chap who makes these things.

In order to not give Ebay any more money I sent him an email - he never responded and that was like a red rag to a bull.

I had somewhere in one of the old sheds an arc welder, I think I had it to mend some gates as it was cheaper than getting a man in.

I dug it out, a 16 amp thingy with some wires - will it work in a 13 amp socket? - probably if I turn it down a bit, there's a big dial on the front with some numbers that mean something to somebody (but not me) turn it left a bit.

I got a bit of steel at a grand cost of about £6 - they make this conveniently that one size square section slides into another - very clever (and damn useful too), I got some grey sticks, Darth Vaders helmet and a hacksaw (no angle grinder - I need the excercise).

With sheer determination I made a sharpening jig as you can see - it is not pretty, it looks rather like the welding witch has been and spat on it but by 'ek it's solid. I used a pillar drill and I also have a tap and die set for doing the locking nuts (1 bolt cut in half, hole in each half an old nail through and you have a jointed locking thingy). Getting the length correct on the spindle jig was tricky - especially getting the hole centred on the 90° angle - it took 2 goes.

It works very well and if you don't have to buy a welder or tools dirt cheap - but most importantly - it was bloody good fun.

So if you get a chance to ever make your own tools have a go - as you can see I am no engineer and even I managed it -not only will you save a few quid you get a warm feeling of satisfaction every time you use it.

I can't recommend a 16 amp appliance in a 13 amp socket for obvious reasons but I am still here to tell the tale