MrJoshua

Full Member

Afternoon all

I've a couple of questions relating to aspects of my penmaking, separate to the pens themselves really, and hope this is the right place to ask!

1) Veneers - I like doing celtic bands but am struggling to get consistent veneer type pieces to insert into the bandsaw cut. The kerf of the cut is 1.2-1.3mm, so I have just tried the lazy option and looked on ebay for "1.2mm veneer" but come up blank. Any time I try to cut suitable pieces they're rarely of a consistent thickness regardless of how I try to cut them (ie what kind of saw/power saw I use).

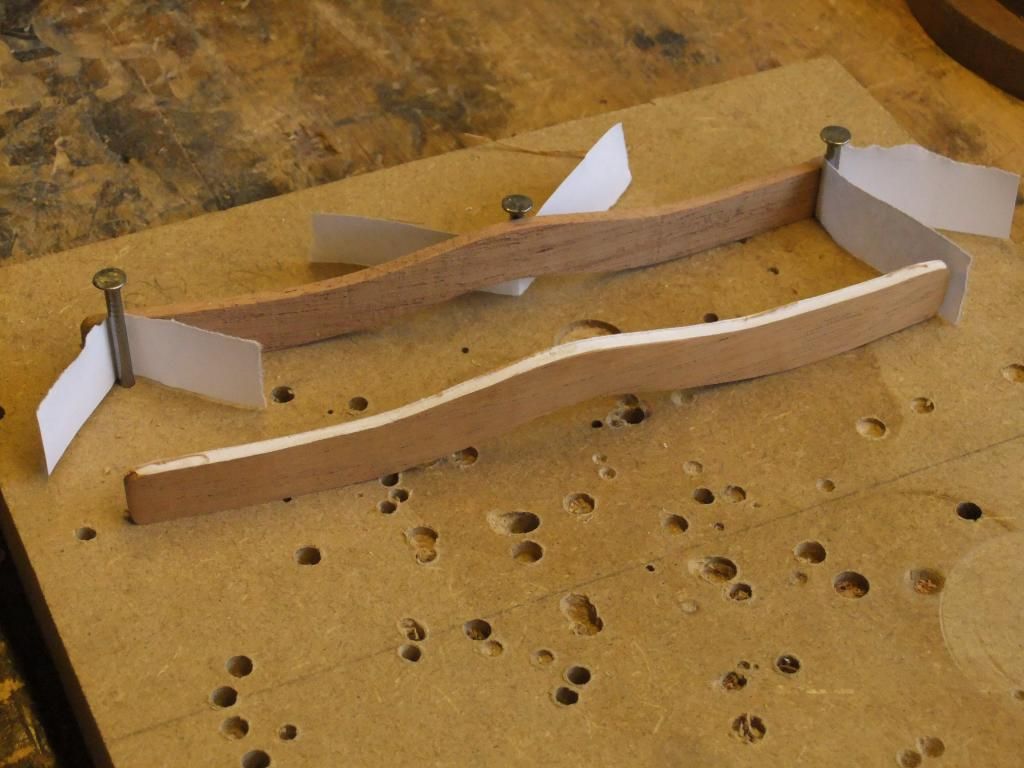

What's the easiest method to get thin accurate slices like this consistently in you guys' experience? I've tried one attempt at glueing two thin sheets of different 0.6mm veneers together to make a thicker layer to slot in but it didn't turn out well for some reason. I think that was more to do with the cut itself being bad on that occasion rather than the insert.

2) Pen boxes - I want to provide my pens in wooden boxes, and was going to buy them in some shape or form as cheap as I could, but haven't found anything that looks ok but doesn't add quite a bit to the price, as anything cheap seems to (understandably) be poor quality, which spoils the overall impression. So kind of two questions here, if you buy wooden pen boxes yourself, can you recommend a supplier of cheap but ok quality boxes, OR, is there a box design where it's very simple & quick to make myself, or where I could do a load of them in one go relatively easily? I've got a table saw (cheap, nasty one), and router/router table (I've very little practical experience using a router though), chop mitre saw, bench belt sander, thicknesser, bandsaw etc, so most power tools I'd likely need I think.

Thanks folks - appreciate any useful input on these two areas!

I've a couple of questions relating to aspects of my penmaking, separate to the pens themselves really, and hope this is the right place to ask!

1) Veneers - I like doing celtic bands but am struggling to get consistent veneer type pieces to insert into the bandsaw cut. The kerf of the cut is 1.2-1.3mm, so I have just tried the lazy option and looked on ebay for "1.2mm veneer" but come up blank. Any time I try to cut suitable pieces they're rarely of a consistent thickness regardless of how I try to cut them (ie what kind of saw/power saw I use).

What's the easiest method to get thin accurate slices like this consistently in you guys' experience? I've tried one attempt at glueing two thin sheets of different 0.6mm veneers together to make a thicker layer to slot in but it didn't turn out well for some reason. I think that was more to do with the cut itself being bad on that occasion rather than the insert.

2) Pen boxes - I want to provide my pens in wooden boxes, and was going to buy them in some shape or form as cheap as I could, but haven't found anything that looks ok but doesn't add quite a bit to the price, as anything cheap seems to (understandably) be poor quality, which spoils the overall impression. So kind of two questions here, if you buy wooden pen boxes yourself, can you recommend a supplier of cheap but ok quality boxes, OR, is there a box design where it's very simple & quick to make myself, or where I could do a load of them in one go relatively easily? I've got a table saw (cheap, nasty one), and router/router table (I've very little practical experience using a router though), chop mitre saw, bench belt sander, thicknesser, bandsaw etc, so most power tools I'd likely need I think.

Thanks folks - appreciate any useful input on these two areas!